In this project, we design and manufacture Fuel feeder, Step grate, Ash hoppers.

The feeder and the gate are driven by cylinders to push a certain amount of garbage into the incinerator through periodic reciprocating push and pull movements, and the feeder can adjust the feeding speed according to the load of the incinerator. The capacity is designed according to each project different situation.

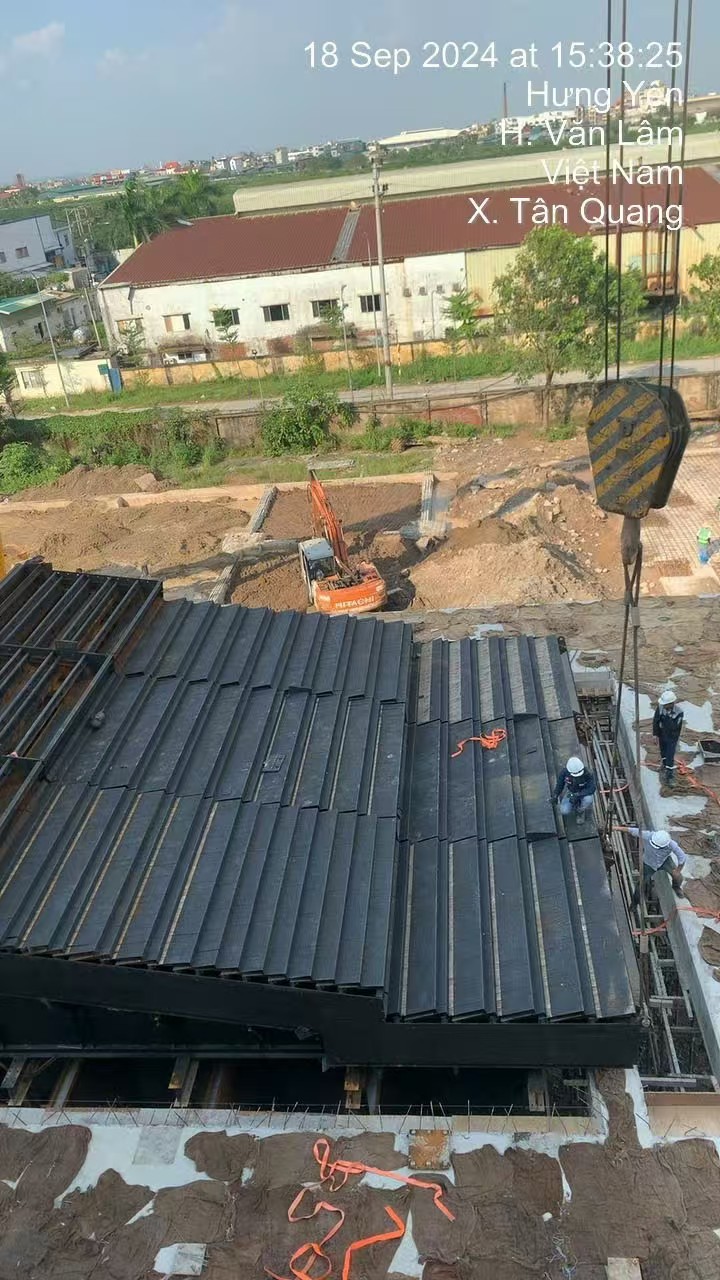

MSW Step grate is a downward-pushing stepped inclined reciprocating grate, the grate is divided into three stages of drying, combustion and burning out stage. We set a height difference between each section of the grate, so that the garbage is scattered after falling and the garbage is pushed to move, and at the same time the garbage is prevented from gathering together to lead to incomplete combustion.

The step grate is driven by hydraulic station, and the three sections of the grate can be controlled independently, so that the movement cycle of the grate can be adjusted according to the combustion state in the furnace. The grate bars is made of high heat-resistant cast steel, which has good wear-resistant, high temperature-resistant and corrosion-resistant properties.

We also have special design regarding the grate thermal expansion, We design the Side sealed absorber set at the two sides grate which use to absorb heat thermal expansion of grate plates.